IT Vizion offers flexible and dependable managed IT services to businesses of all sizes seeking to optimize and enhance IT operations.

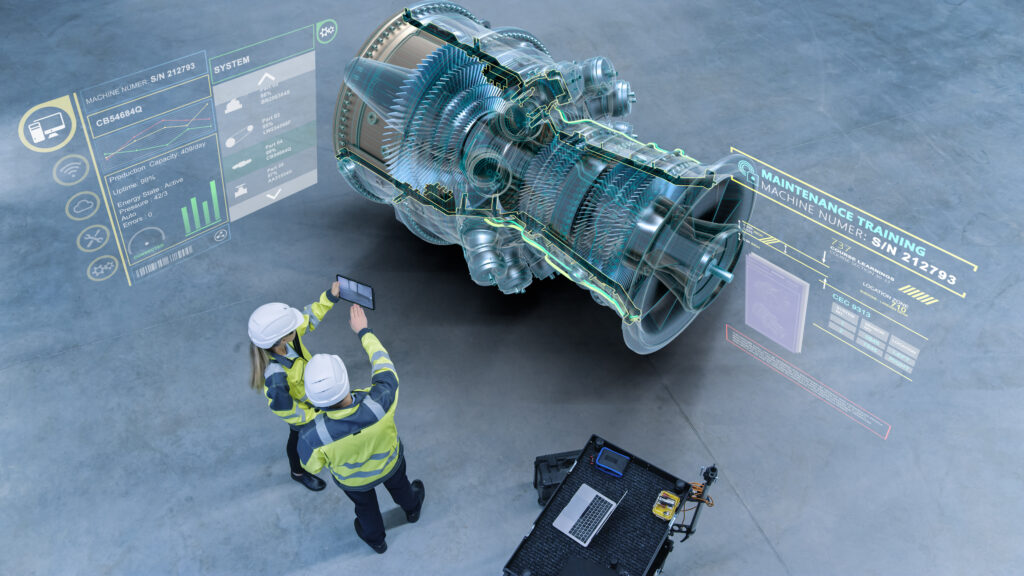

IT Vizion specializes in aligning and optimizing OT-IT integration. We have a proven track record of introducing data-driven innovations that help companies achieve better business outcomes.

- Plant Information Services

- Technology Services

BUSINESS CONSULTING SERVICES

• Solution Architecture

• System & Solution Audits

• Application Support

• Technical Innovation Introduction

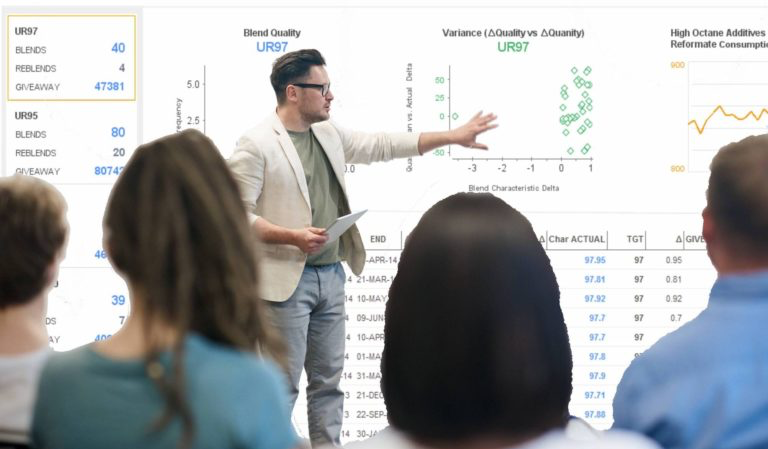

• Enterprise Operations Intelligence (OI)

• Data Integration & Visualization

• Operational Excellence and KPI Software Solutions

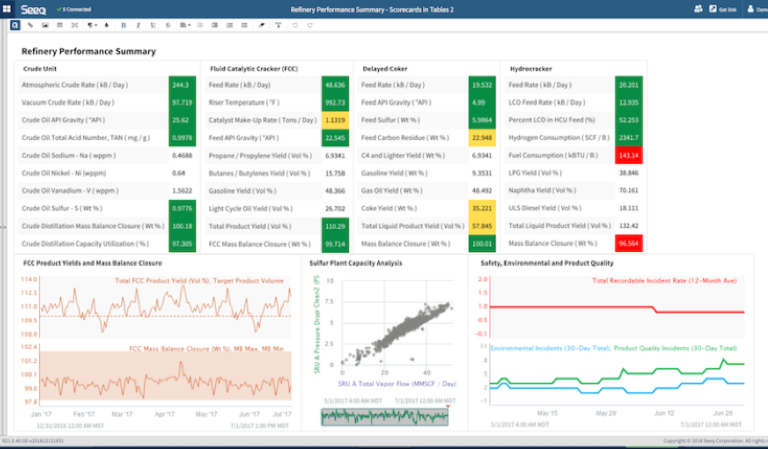

SEEQ ANALYTICS SERVICES

• SEEQ Launch Services

• Certified SEEQ Services

• SEEQ Training

• SDL Python Extensions

• Solution Support

PI SYSTEM SERVICES

• PI System Architecture

• Installation & configuration

• Administration & Support

• PI Application Development

• Asset Framework Build

• PI Vision screen build

SIEMENS XHQ SERVICES

• XHQ System Architecture

• Installation & configuration

• Administration & Support

• XHQ Application Development

• Information Model Build

• ANS, eLOGS, TM, PA

• KPI & Dashboards, trending

• TDC and Experion View Conversions

Consulting

Engage IT Vizion, and benefit from our expertise to help you navigate today’s technology landscape.

IT Vizion relies on a consultative approach that connects people and technology to develop a custom solution suitable for your business requirements, budget, and timeline.

Our experts seek to understand your business first, in order to identify and bundle technology services that address your IT and Network needs.

Managed Services

Our Managed IT Solution provides a comprehensive support solution to customers. This model provides the customer with a solution that minimizes technical and financial risks. VizionPro services are performed 24×7, 365 days a year by experienced, certified engineers, who use enterprise-class technologies and follow proven processes to ensure 24×7 uptime for servers, network devices, infrastructure, and business applications.

Application Services

IT Vizion offers software development services, dedicated development teams, QA/Testing and IT consulting using the outsourcing business model. Our philosophy is based on the principles of high quality of deliverables, advanced project management techniques, cutting edge tools and technologies, and dedication to project success.

IT Vizion is a leading OT-IT system integrator for global Oil&Gas, Chemicals, and Manufacturing firms.

Copyright ©2024 IT Vizion

Contact info

Let’s connect. Contact IT Vizion today.

- We Operate Worldwide

- +1 (951) 256-4320

- contact@itvizion.com